Look at a knife steel chart before choosing a knife steel because you should know its composition and hardness . There are different points on the Rockwell scale, depending on the purpose of the knife.

The following table lists the most common knife steels, along with the amount of each. It also includes the percentage of carbon and Chromium and other important attributes.

Most common knife steel

-

Carbon

-

Chromium

-

Chromium alloys

-

Carbon content

-

Hardness

If you’re planning to make production knives, you should pay attention to the Carbon and Chromium content. However, it may not be enough to find the perfect knife steel for your needs.

Carbon

Before buying a new knife, it is important to understand what type of steel you need. Different types of steel have different hardness levels, and it is important to know how you plan to use your knife to determine which one is best for your needs. A knife with a high carbon content, for example, can be very rigid and can chip easily. If you’re buying a knife for everyday use, you should look for a knife with a lower carbon content to keep it from bending or breaking when you’re using it.

Another important consideration is the knife’s performance. Stainless steel blades have superior corrosive resistance, but their edge retention is limited. This is because stainless steel requires a certain amount of carbon in order to resist corrosion. But carbon is not the only consideration. Heat treatment is also crucial. It’s essential to compare knife steel composition to other similar steels to ensure you’re getting the best quality. The chart shows the most common temperatures that will cause your knife to rust, and the type of heat treatment used to make it.

Another important characteristic is corrosion resistance. While the highest-grade carbon steel is essentially the hardest steel, too much carbon will cause it to break or chip. If a knife is too hard, it’s likely to chip or break when used frequently. If it rusts under the right conditions, it will eventually break. So it’s best to choose a knife with a higher carbon content. The higher the carbon content, the harder the knife will be, but the trade-off is increased strength and anti-corrosion capabilities.

Chromium Steel

A knife’s performance is determined by the type of steel it is made of. Steel is a carbon and iron alloy that is enriched with certain elements, such as chromium. Different types of steel have different chromium content, depending on their use. While chromium increases corrosion resistance, it also absorbs some of the chromium in carbon steels. Chromium is added to the steel during the manufacturing process, making it a superior choice for blades.

Stainless steel contains the most chromium, and is the most common. Unlike carbon steel, stainless steel does not rust in air. Its sharpness isn’t very long-lasting, but it’s better than low-quality carbon steel. This steel also requires less sharpening than other types of knife steel, and can easily be sharpened without using power tools. 420 stainless steel, used in many Buck knives, has less chromium than 440. It’s tougher than 440, but will dull quickly.

Carbon is the main element in steel, and varies in percentage to create various properties. Chromium is an anti-rust additive, while manganese makes blades harder and more durable. High amounts of manganese, on the other hand, can make a knife steel brittle and prone to chipping on hard surfaces.

Carbon-based knife steel contains a high amount of carbon, but does not have the chromium content that stainless steel needs to resist corrosion. Additionally, a high amount of carbon also leads to rusting, which is undesirable for a knife’s performance.

Some chromium steels have a five-digit SAE/AISI designation instead of two, which indicates their carbon content. When comparing chromium content between two different knives, you can choose the best for your needs. You can even choose a knife that is made of different materials. Fortunately, there are plenty of high-quality stainless steel options available on the market. The main consideration is whether it is a good choice for your purposes.

Chromium alloys

Many knives use the SAE/AISI designation of D2, a Japanese tool steel containing almost enough chromium to be considered stainless steel. While D2 knife steel is tough and corrosion-resistant, it lacks hardness in comparison to cheaper alloys. Nevertheless, it retains a first-class edge for a long time. While D2 is prone to rust, it is still a good choice for a knife. This steel contains 12% chromium.

Other popular grades of steel used in knifemaking include CTS-204P, CPM-20CV, and ATS 34. CTS-204P is comparable to CPM-20CV, but has a higher percentage of vanadium. While M390 is very hard, it is difficult to sharpen, making it an ideal choice for knives that will be used frequently in salt water environments. ATS 34 is the toughest type of steel, although it also has an extra dose of chromium.

Another type of alloy is niobium. Niobium is a silver-gray transitional metal that can absorb chromium and contribute toughness. Niobium is a silver-gray transitional metal that adds toughness and improves corrosion resistance. Chromium is an essential element for knife steel, but some knives do not contain it. While all stainless steels have high chromium content, these blades are still susceptible to rusting when exposed to extreme environments.

SAE 300 series stainless steel is made from chromium-nickel alloy. It is made with a ferritic crystalline structure. It contains chromium and nickel, and has a higher corrosion resistance and harderness than austenitic structures. SAE 301 Full Hard is commonly used for knife blades and stainless trays. It is also more pliable than SAE 400 series stainless steel.

Carbon content

Knife steels can vary in the amount of carbon they contain. High carbon steels are tougher and more resistant to elements than low carbon steels. High carbon steels are typically used for knives that are subjected to aggressive environments. They can contain chromium, nickel, and titanium in various ratios. However, they can also contain other elements, including aluminum, silicon, and copper. In most cases, higher carbon content does not affect a knife’s hardness.

Some common Japanese carbon steels contain up to 1.3% carbon. CPM 4V, for example, has 0.74% carbon and 0.54% vanadium, which are good indicators of toughness and heat treatment characteristics. Alternatively, CPM 9V contains less carbon, and more vanadium to improve toughness. Another proprietary knife steel is CPM CRU-WEAR, which is an upgraded version of conventional Cru-Wear. The alloys added to this steel increase its wear resistance and ductility.

Stainless steel is another common type of knife steel. The carbon content in this steel ranges from 0.05% to 2.1%. Most knives are made of carbon steel, and manufacturers often refer to all of their steel as such. Carbon steel is hard, but other materials can add hardness and corrosion resistance. A hard knife will also be brittle and prone to rust. A good carbon steel is a balanced blend of high carbon content and minimal additions as describe in our knife steel chart above.

Another high carbon knife steel is ATS 34. This tool steel has a carbon content of 1.5 percent. This steel has an edge-holding performance comparable to ATS 34 and is considered tough enough for surgical use. This steel also has a high hardness level. In fact, it is almost as tough as CPM S90V steel. It is also more rust-resistant than CPM S90V, and is used in most cases.

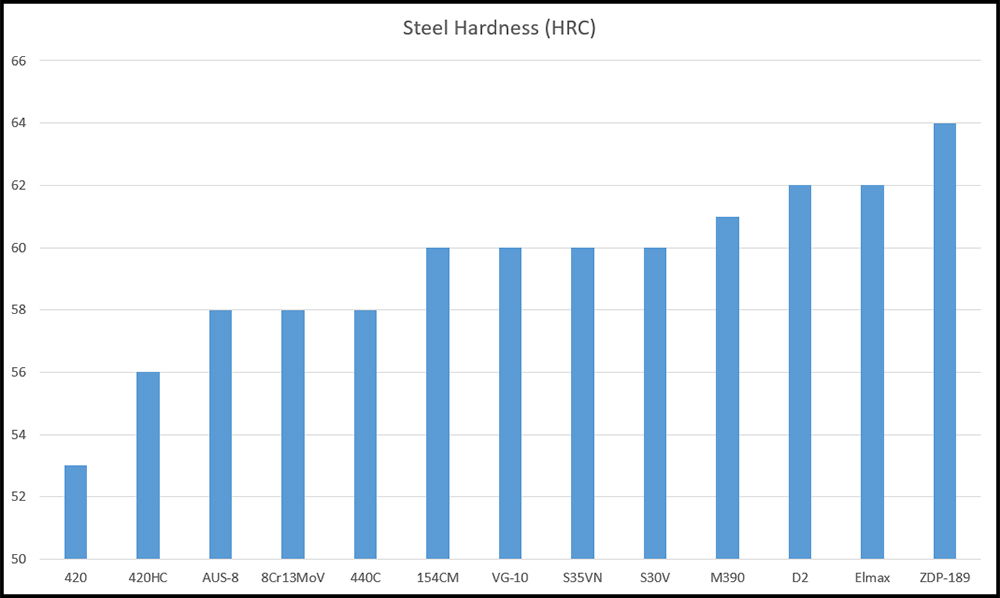

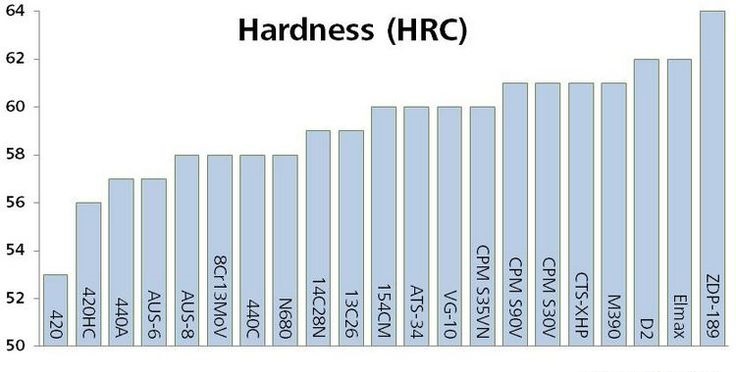

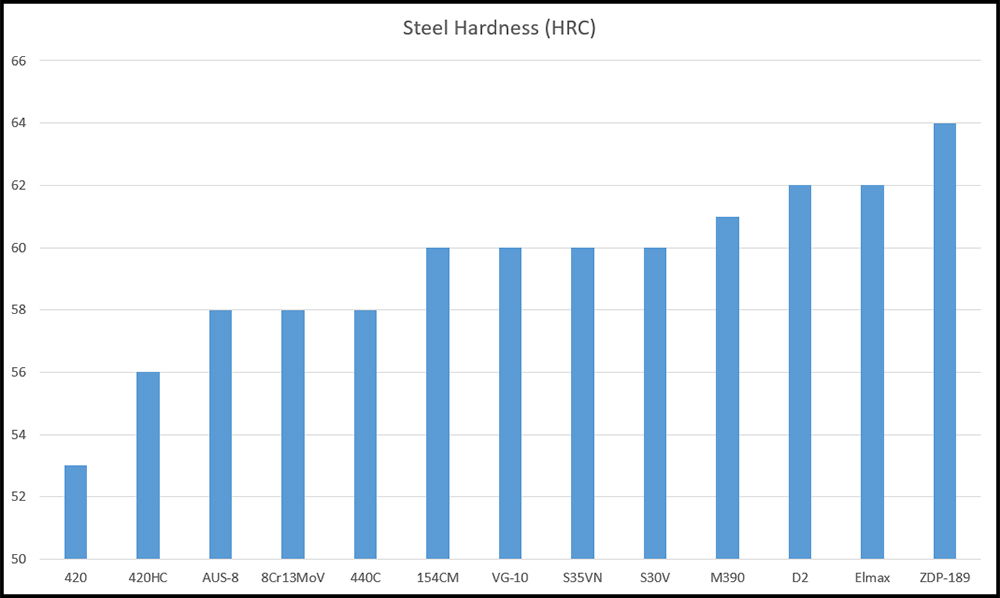

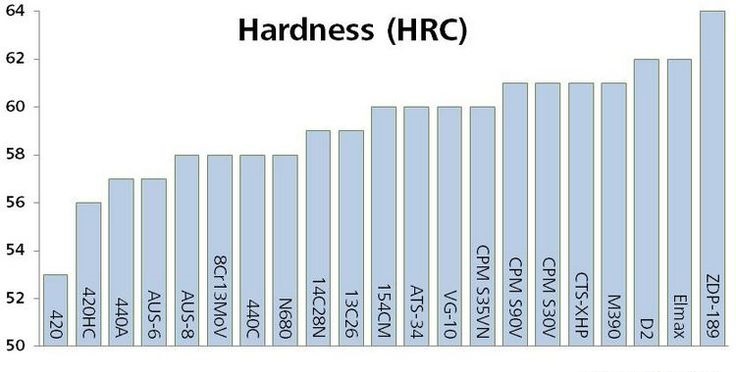

Knife Steel Hardness

To choose the best knife steel, determine its hardness. Its hardness is measured on the Rockwell scale, and the harder the steel, the better the knife will hold its edge. Harder steel will hold an edge longer but is less durable. Knife steel with a HRC rating of 55 or higher will hold an edge longer, but they are more difficult to sharpen when dull. Knives made of soft steel are easier to maintain, but will lose their sharpness more easily.

A high-quality knife steel will also be tough. It is a measure of its resistance to breakage, chipping, and cracking. Toughness is the opposite of brittleness. However, testing for toughness is not standardized, and the results are often difficult to correlate with hardness measurements. Common toughness tests include various impact and bend fracture tests. In general, knives with a 57-59 HRC hardness rating are recommended, but some cheaper models may be as low as 50.

In general, the higher the Rockwell number, the more durable the knife. This is especially true of high-carbon steel knives. A good example of this is the Benchmade 581 Barrage, which is made of M390 steel. This knife is one of the few knives available with M390 steel. A similar model is made of CPM-S35VN steel. However, there are other hardness grades available, such as D2 and HRC.

In addition to the hardness, knife steel also has some other properties that determine its performance. For instance, knife steels are classified based on their toughness and wear resistance. They are also rated by their resistance to corrosion. All these factors can make the difference between a good knife and a great one. And, in general, the tougher the knife steel, the better. So, how do you decide which knife steel is best? Consult your knife steel chart beforehand.

The post The Knife Steel Chart Breakdown appeared first on KnifeGenie.com.

Look at a knife steel chart before choosing a knife steel because you should know its composition and hardness . There are different points on the Rockwell scale, depending on the purpose of the knife.

The following table lists the most common knife steels, along with the amount of each. It also includes the percentage of carbon and Chromium and other important attributes.

Most common knife steel

If you’re planning to make production knives, you should pay attention to the Carbon and Chromium content. However, it may not be enough to find the perfect knife steel for your needs.

Carbon

Before buying a new knife, it is important to understand what type of steel you need. Different types of steel have different hardness levels, and it is important to know how you plan to use your knife to determine which one is best for your needs. A knife with a high carbon content, for example, can be very rigid and can chip easily. If you’re buying a knife for everyday use, you should look for a knife with a lower carbon content to keep it from bending or breaking when you’re using it.

Another important consideration is the knife’s performance. Stainless steel blades have superior corrosive resistance, but their edge retention is limited. This is because stainless steel requires a certain amount of carbon in order to resist corrosion. But carbon is not the only consideration. Heat treatment is also crucial. It’s essential to compare knife steel composition to other similar steels to ensure you’re getting the best quality. The chart shows the most common temperatures that will cause your knife to rust, and the type of heat treatment used to make it.

Another important characteristic is corrosion resistance. While the highest-grade carbon steel is essentially the hardest steel, too much carbon will cause it to break or chip. If a knife is too hard, it’s likely to chip or break when used frequently. If it rusts under the right conditions, it will eventually break. So it’s best to choose a knife with a higher carbon content. The higher the carbon content, the harder the knife will be, but the trade-off is increased strength and anti-corrosion capabilities.

Chromium Steel

A knife’s performance is determined by the type of steel it is made of. Steel is a carbon and iron alloy that is enriched with certain elements, such as chromium. Different types of steel have different chromium content, depending on their use. While chromium increases corrosion resistance, it also absorbs some of the chromium in carbon steels. Chromium is added to the steel during the manufacturing process, making it a superior choice for blades.

Stainless steel contains the most chromium, and is the most common. Unlike carbon steel, stainless steel does not rust in air. Its sharpness isn’t very long-lasting, but it’s better than low-quality carbon steel. This steel also requires less sharpening than other types of knife steel, and can easily be sharpened without using power tools. 420 stainless steel, used in many Buck knives, has less chromium than 440. It’s tougher than 440, but will dull quickly.

Carbon is the main element in steel, and varies in percentage to create various properties. Chromium is an anti-rust additive, while manganese makes blades harder and more durable. High amounts of manganese, on the other hand, can make a knife steel brittle and prone to chipping on hard surfaces.

Carbon-based knife steel contains a high amount of carbon, but does not have the chromium content that stainless steel needs to resist corrosion. Additionally, a high amount of carbon also leads to rusting, which is undesirable for a knife’s performance.

Some chromium steels have a five-digit SAE/AISI designation instead of two, which indicates their carbon content. When comparing chromium content between two different knives, you can choose the best for your needs. You can even choose a knife that is made of different materials. Fortunately, there are plenty of high-quality stainless steel options available on the market. The main consideration is whether it is a good choice for your purposes.

Chromium alloys

Many knives use the SAE/AISI designation of D2, a Japanese tool steel containing almost enough chromium to be considered stainless steel. While D2 knife steel is tough and corrosion-resistant, it lacks hardness in comparison to cheaper alloys. Nevertheless, it retains a first-class edge for a long time. While D2 is prone to rust, it is still a good choice for a knife. This steel contains 12% chromium.

Other popular grades of steel used in knifemaking include CTS-204P, CPM-20CV, and ATS 34. CTS-204P is comparable to CPM-20CV, but has a higher percentage of vanadium. While M390 is very hard, it is difficult to sharpen, making it an ideal choice for knives that will be used frequently in salt water environments. ATS 34 is the toughest type of steel, although it also has an extra dose of chromium.

Another type of alloy is niobium. Niobium is a silver-gray transitional metal that can absorb chromium and contribute toughness. Niobium is a silver-gray transitional metal that adds toughness and improves corrosion resistance. Chromium is an essential element for knife steel, but some knives do not contain it. While all stainless steels have high chromium content, these blades are still susceptible to rusting when exposed to extreme environments.

SAE 300 series stainless steel is made from chromium-nickel alloy. It is made with a ferritic crystalline structure. It contains chromium and nickel, and has a higher corrosion resistance and harderness than austenitic structures. SAE 301 Full Hard is commonly used for knife blades and stainless trays. It is also more pliable than SAE 400 series stainless steel.

Carbon content

Knife steels can vary in the amount of carbon they contain. High carbon steels are tougher and more resistant to elements than low carbon steels. High carbon steels are typically used for knives that are subjected to aggressive environments. They can contain chromium, nickel, and titanium in various ratios. However, they can also contain other elements, including aluminum, silicon, and copper. In most cases, higher carbon content does not affect a knife’s hardness.

Some common Japanese carbon steels contain up to 1.3% carbon. CPM 4V, for example, has 0.74% carbon and 0.54% vanadium, which are good indicators of toughness and heat treatment characteristics. Alternatively, CPM 9V contains less carbon, and more vanadium to improve toughness. Another proprietary knife steel is CPM CRU-WEAR, which is an upgraded version of conventional Cru-Wear. The alloys added to this steel increase its wear resistance and ductility.

Stainless steel is another common type of knife steel. The carbon content in this steel ranges from 0.05% to 2.1%. Most knives are made of carbon steel, and manufacturers often refer to all of their steel as such. Carbon steel is hard, but other materials can add hardness and corrosion resistance. A hard knife will also be brittle and prone to rust. A good carbon steel is a balanced blend of high carbon content and minimal additions as describe in our knife steel chart above.

Another high carbon knife steel is ATS 34. This tool steel has a carbon content of 1.5 percent. This steel has an edge-holding performance comparable to ATS 34 and is considered tough enough for surgical use. This steel also has a high hardness level. In fact, it is almost as tough as CPM S90V steel. It is also more rust-resistant than CPM S90V, and is used in most cases.

Knife Steel Hardness

To choose the best knife steel, determine its hardness. Its hardness is measured on the Rockwell scale, and the harder the steel, the better the knife will hold its edge. Harder steel will hold an edge longer but is less durable. Knife steel with a HRC rating of 55 or higher will hold an edge longer, but they are more difficult to sharpen when dull. Knives made of soft steel are easier to maintain, but will lose their sharpness more easily.

A high-quality knife steel will also be tough. It is a measure of its resistance to breakage, chipping, and cracking. Toughness is the opposite of brittleness. However, testing for toughness is not standardized, and the results are often difficult to correlate with hardness measurements. Common toughness tests include various impact and bend fracture tests. In general, knives with a 57-59 HRC hardness rating are recommended, but some cheaper models may be as low as 50.

In general, the higher the Rockwell number, the more durable the knife. This is especially true of high-carbon steel knives. A good example of this is the Benchmade 581 Barrage, which is made of M390 steel. This knife is one of the few knives available with M390 steel. A similar model is made of CPM-S35VN steel. However, there are other hardness grades available, such as D2 and HRC.

In addition to the hardness, knife steel also has some other properties that determine its performance. For instance, knife steels are classified based on their toughness and wear resistance. They are also rated by their resistance to corrosion. All these factors can make the difference between a good knife and a great one. And, in general, the tougher the knife steel, the better. So, how do you decide which knife steel is best? Consult your knife steel chart beforehand.

![]()